Solutions to enable productive and profitable manufacturing.

Smart 24/7 Monitoring

- Correlate status of the environment with the production output quality (3D Printers, sensitive measurement equipment, clean rooms)

- Monitor occupancy of a space to track utilization and ensure social distancing (as required by business policy)

- Ensure there are no water leaks or floods in critical areas of the facility (UPC – battery backup, server rooms, lasers, scopes, clean rooms, 3D printing area, etc.) to reduce water damage and related insurance costs.

Dynamic Notification

- The ideal resource / stakeholder is informed via text and/or email based on need and required task (optimize environmental conditions, material replenishment, maintenance, repair, or clean up) to ensure a timely response to issues.

Smart Technology

- A scalable and expandable wireless system enabling your building to be IoT ready.

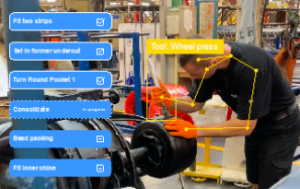

- Visual AI

Ideal Customer

- Facilities with Additive, Prototype, Production, and/or Paint and Dip functions.

Shop Floor Analytics.

Human actions and environmental conditions on the production floor are a blind spot in factory analytics.

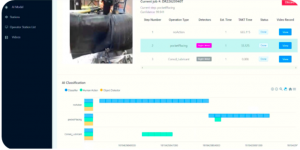

Our system digitizes human actions providing data on operator and line performance, and collects environmental data.

Cutting edge analytics and visualization tools enable data driven productivity improvements

Deploying our smart manufacturing solution is like having a QC engineer, QA engineer, and trainer at every station on the production floor.

Essentially, productivity is about identifying the smallest inefficiencies and making positive changes.

With our AI enabled vision, IoT sensors, and analytics system our clients can now do this at scale with a demonstrated RoI on yield, utilization, training time, and operating costs.

How? By capturing data and unlocking its value into actionable activity.

Return on Investment (RoI).

Real-Time Assembly Analytics

Traceability and Scheduling

Skill Retention and Training

Operations Maintenance

Manual assembly defect detection and prevention

Automated time and motion data in real time

Wireless IoT sensors monitor for ideal environmental condition

Trace failures and root causes

Protocol adherence and TAKT times

Environmental data collected by sensors for debug and quality analysis

Human actions classified and categorized

Best practices isolated and captured

IoT sensors to monitor for water leaks and floods, temperature, humidity, and air quality

Notification engine to notify designated stakeholders as required

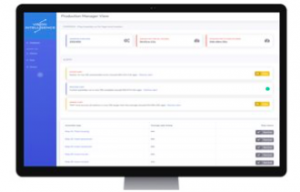

Work order management module to track KPI

25%

IMPROVEMENT IN YIELD

25%

IMPROVEMENT IN UTILIZATION

50%

REDUCTION IN TRAINING TIME

80%

REDUCTION IN OPERATING COSTS

Product Offering

Business Intelligence Layer

One-off purchase of hardware and a subscription model for each application used, lowers the barriers for SMEs.

Included in the subscription is the camera and sensor management dashboard and notification engine to alert stakeholders of any recommendations, issues or dramatic changes.

Application Layer

Physical (SFDC) Layer

IoT Hardware